產(chǎn)品詳情

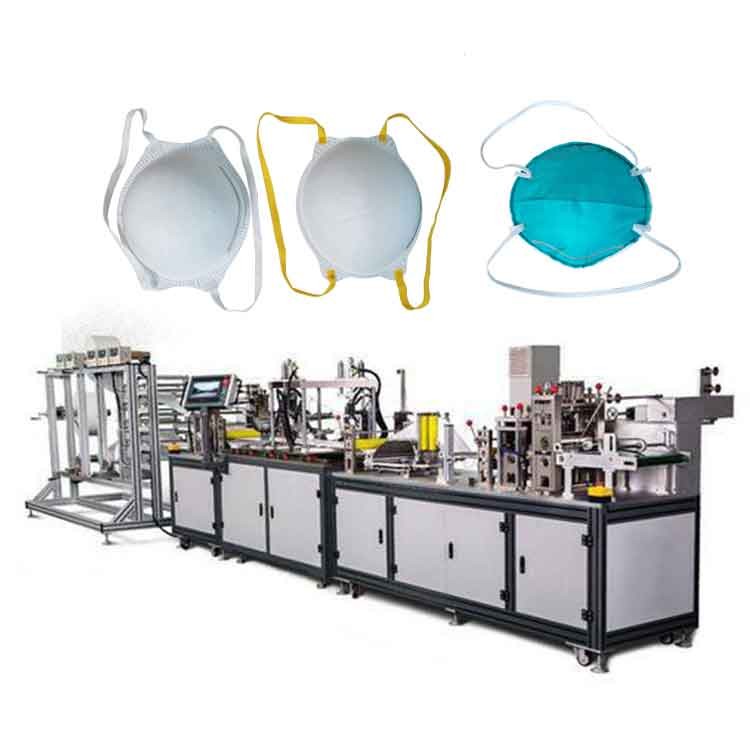

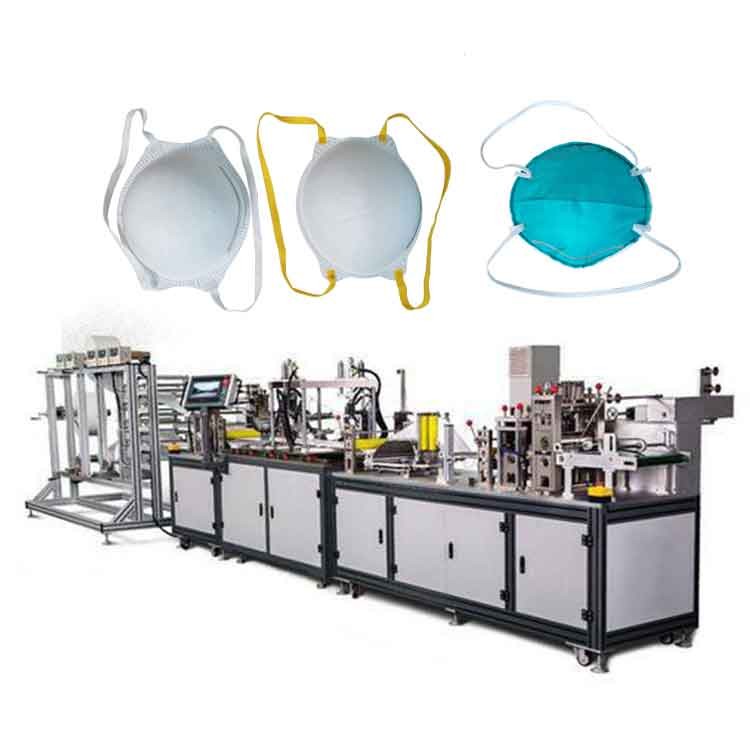

全自動杯型口罩機

Automatic Cup Mask Machine

ACMM-6

設備技術規(guī)格書

Technical specification of equipment

一���、基本介紹Basic introduction

全自動杯型口罩機:秦泰盛公司依據(jù)客戶需求,通過PLC編程控制,整個設計分為前段與后段��,前段分為自動送料���,一次定型--二次定型--三次定型--超聲波焊接--沖切--杯狀口罩輸出���;后段分為:焊接鼻梁條--移印LOGO(選配)--焊接左/右耳帶--沖孔(選配)--焊接呼吸閥(選配)--成品輸出。成功研發(fā)設計出全新的全自動杯型口罩機,本機具有自動化程度高�,操作簡單,根據(jù)客戶的不同要求��,可以通過增加或減少機臺的數(shù)量來達到客戶的要求�����,具備更人性化的特點。

Automatic cup mask machine: According to customer needs, Qin-Tech is controlled by PLC programming,the whole design is divided into front section and back section,the first shaping -- second shaping -- third shaping -- ultrasonic welding -- punching cutting -- cup mask output;

The back ?section is divided into: welding nose bridge strip -- printing LOGO (optional) -- welding left/right ear strip -- punching (optional) -- welding breathing valve (optional) -- finished product output. successfully developed and designed a new automatic cup mask machine ,which has the characteristics of high degree of automation, simple operation and more user-friendly.

二�����、設備技術參數(shù): Technical Parameters

?材料:兩層定型棉一層熔噴布或一層針刺棉一層熔噴布一層填充棉一層無紡布�����。

Material:Two layers of set cotton, one layer of melt- blown or one layer of needled cotton , one layer of melt- blown, one layer of fiberfill and one layer of non-woven fabric.

?電壓:AC 220V,50HZ

Voltage: AC 220V, 50HZ

?重量:3500KG

Weight: 3500KG

功率:20 KW

?外觀尺寸:

12000(L)x6500(W)2300(H) ;

重量:3500kg

Size:

Feeder: 12000(L)x6500(W)X2300(H); Weight:310kg

?效率: 10-18pcs/min

Efficiency: 10-18pcs/min

?產(chǎn)品規(guī)格:可依據(jù)客戶要求進行定制

Product specifications: can be customized according to customer requirement.

?適用行業(yè):一次性醫(yī)療防護用品

Applicable industries: disposable medical protective equipment

五�、設備特點:Features of equipment

1、整機設計由前段與后段部分組成����,方便搬運與調(diào)試�。

The whole machine design is composed of front section and back section, which is convenient for handling and debugging .

2、自動化程度高��,整機一人操作�。

High degree of automation, the whole machine is operated by one person.

3、分開定型���,以致熔噴布不被破壞�,保證產(chǎn)品的質(zhì)量����。

Separate shaping, so that the melt blown cloth will not be damaged, and ensure the quality of products.

4��、采用模塊式設計��,針對不同的口罩��,可以采用增加或獨立設計模塊的方

式來增減功能���。

Using modular design, for different masks, can be increase or

decrease functions by adding or independently designing modules.

5、機架采用整體焊接工藝�����,穩(wěn)定高效經(jīng)久耐用�。可長時間高效不間斷的運行�。

The frame adopts the overall welding process, which is stable, efficient and durable. It can run efficiently for a long time without interruption.

六、原材料規(guī)格(建議):Raw material specifications (recommended)

由外至內(nèi)(材料幅寬220mm)

From outside to inside (material width 220mm)

第一層

The first ply 180-220克 針刺棉(或定型棉)

180-220 g needled cotton

(or Setting cotton )

第二層

The second ply 50-60克熔噴布

50-60g melt-blown

第三層

The third ply 50-60克填充棉

50-60g fiberfill

第四層

The fourth ply 30-40克無紡布

30-40g non-woven 最內(nèi)層(或最外層)(選配)

Innermost layer

(or outermost layer) (optional)

八��、設備使用環(huán)境:Equipment use environment

1.10萬級無塵車間使用����。

1. Use in the 100,000 class clean room.

2.溫度:室溫環(huán)境,濕度:40%-80%����。

2. Temperature: room temperature environment, humidity: 40%-80%.

3.電源:AC220V��,50Hz ����。

3. Power supply: AC220V, 50Hz.

4.氣壓:≥0.6MPa ��。

4. Air pressure: ≥0.6MPa.

十����、設備操作要求:Equipment operation requirements

1. 可實現(xiàn)手動、自動及單動運行相互切換的操作模式�,故障報警需在人機界面顯示等;

1.It can realize the operation mode of manual, automatic and single-action operation switching each other. The alarm should be displayed in the man-machine interface.

2. 采用工控機實現(xiàn)與PLC的實時通訊���,通過觸摸屏實現(xiàn)人機對話,各項設置操作需簡單方便����;

2. Adopting industrial computer to realize real-time communication with PLC, realize man-machine dialogue through touch screen, each setting operation needs to be simple and convenient;

3.設備符合國家有關機電設備的安全標準要求;

3. The equipment complies with the national safety standards for electromechanical equipment;

十一����、其他要求:other requirements

1.本設備驗收標準:設備組裝調(diào)試完成前一周供方通知需方準備好生產(chǎn)物料��,按技術要求進行驗收���,驗收合格,需方自提發(fā)貨����;

The acceptance standard of the equipment: one week before the completion of the equipment assembly and debugging, the supplier shall notify the buyer to prepare the production materials, carry out the acceptance according to the technical requirements, and the buyer shall deliver the products by itself.

2.設備驗收由供需雙方指定技術人員進行參與并簽署驗收報告;

2.The acceptance of the equipment shall be attended by technicians designated by both parties and the acceptance report shall be signed.

十二����、安裝調(diào)試和培訓:Installation, debugging and training

由供方技術人員負責遠程指導需方人員進行安裝,調(diào)試�;調(diào)試用料由需方提供;

The supplier's technicians are responsible for the remote guidance of the buyer's personnel for installation and debugging; The commissioning materials shall be provided by the buyer.

十三����、質(zhì)量保證和售后服務 :Quality assurance and after-sales service

1.設備的保修期限為半年(非正常使用造成損壞及耗材除外;超聲波控制器保修3個月)���;

1.The warranty period of the equipment is half a year (except damages caused by abnormal use and consumables; Ultrasonic controller are guaranteed for 1 months, Welding head and transducer are not warranted);

2.接到設備品質(zhì)異常����,供需雙方協(xié)商解決;

2. Receiving disorder of equipment, the supplier and the buyer shall negotiate to solve the problem.

3. 保修期滿后���,供方對設備的維修收取人工和交通等費用�,涉及設備相關配件的更換或購買�,供方僅收取成本費用。

3. After the expiration of the warranty period, the supplier shall charge labor and transportation fees for the maintenance of the equipment. In case of replacement or purchase of accessories related to the equipment, the supplier shall only charge costs.

=======END=======